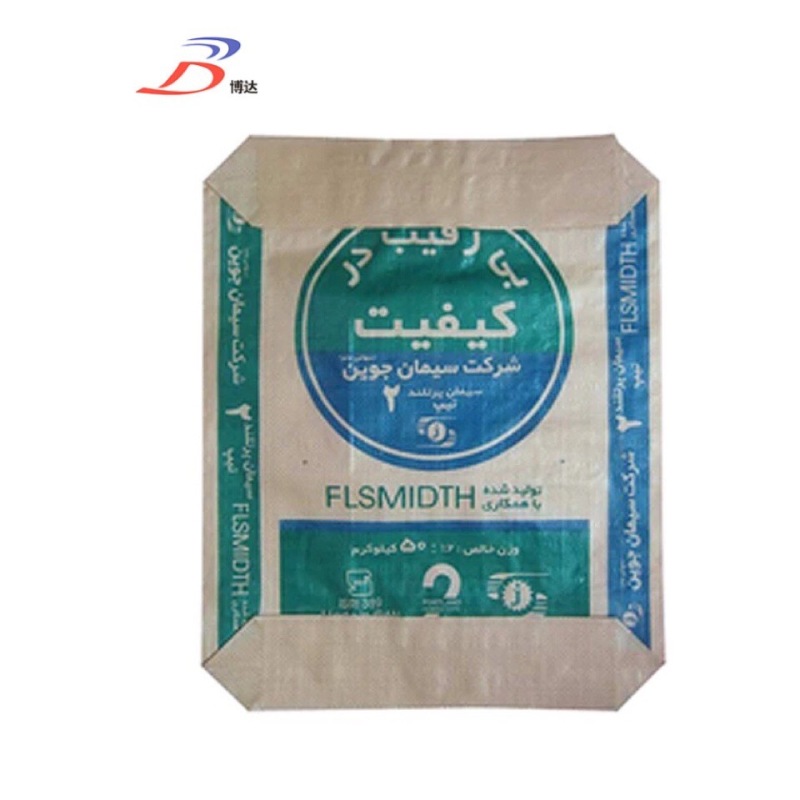

Block Bottom Star Cement Paper bags Price

Model No.:BBVB

Application:Promotion

Feature:Moisture Proof

Material:PP

Shape:Plastic Bags

Making Process:Plastic Packaging Bags

Raw Materials:Polypropylene Plastic Bag

Bag Variety:Your Bag

Length:300mm To 600mm

Width:430mm To 910mm

Top:Hot Air Welding

Bottom:Hot Air Welding

Printing Type:Gravure Printing On One Or Two Sides, Up To 8 Colors

Mesh Size:8×8, 10×10

Sample:Free

Delivery:As Customer

FABRIC COLOR:White Or Beige

Size:Customized

Additional Info

Packaging:500PCS/Bales

Productivity:2500,000 per week

Brand:boda

Transportation:Ocean,Land,Air

Place of Origin:china

Supply Ability:3000,000PCS/week

Certificate:BRC,FDA,ROHS,ISO9001:2008

HS Code:6305330090

Port:Xingang Port

Product Description

The square bottom valve Sack is a high-strength environmentally friendly packaging bag that is popular in the world today. The square bottom valve Bag can be used for mechanized assembly line filling and automatic palletizing. The use of square bottom valve Bag in the cement packaging process can not only reduce the “fleeing” of dust for cement companies, but also achieve perfect stacking.

50 kg cement bag is our popular bag, is our main product .Although they are used to hold 50 kg of cement, the size and thickness of the woven bags are different for each manufacturer because of the difference in cement density and the difference in automatic filling equipment

We’re using the most advanced Stallinger equipment ,From drawing to weaving to coating .On the one hand, the quality of the bag is guaranteed, on the other hand, the speed of making the bag is improved

Woven Poly Bags are a good option for a larger mesh product. Dusty products such as Rice Bran tend to sift through the weave of a Lime PP Sack . Our Building material bag usually come in and 800 or 850 denier with an Anti-Skid twist in the weave, heat cut or hemmed tops, and white in color

Block Bottom Cement BagThe light weight laminated polypropelene bags manufactured by us

offers an innovative andcosteffectivesolutionforthepackagingofcement. Block Bottom Valve Bag possess specialliningthat resist humid conditionsand

helpsinprovidinglongershelflifetothepackedproducts

25kg cement bag from boda are made from best virgin quality raw material. Specially designed for packaging cement, Cement Valve Bag comes with a valve and automatic locking system.

Capacity of Polypropylene Cement Sack/ PP cement Bag : 25kg,50kg,50LB,30kg,40kg,or pp block bottom Valve cement sack as customers demand.

Warmly welcome customer from all over the world to visit our factory .

Our own factory: founded in 1991, 35,000 square meters area, advanced equipment AD*STARLINGER from extrusion to packing, accept any custom order for Pp woven block bottom valve bag, quick delivery.

our AD*Star Bag 50KG speification:

| Length | 63 cm |

| Width | 50 cm |

| Bottom Height | 11 cm |

| Mesh | 10×10 |

| Bag Weight: | 80 ± 2 grams |

| Color | Beige or White |

If customers’ have special demand of the Block bottom valve bag,please let me know,there have demand for Cement Packing Bag I will make a new price to you

Looking for ideal Block Bottom Paper Bags Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the PP Woven Block Bag are quality guaranteed. We are China Origin Factory of Star Cement Price Per Bag. If you have any question, please feel free to contact us.

Product Categories : Block Bottom Valve Bag > Block Bottom Cement Bag

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags